Five Star Plastics provides superior rapid tooling services at highly competitive prices.

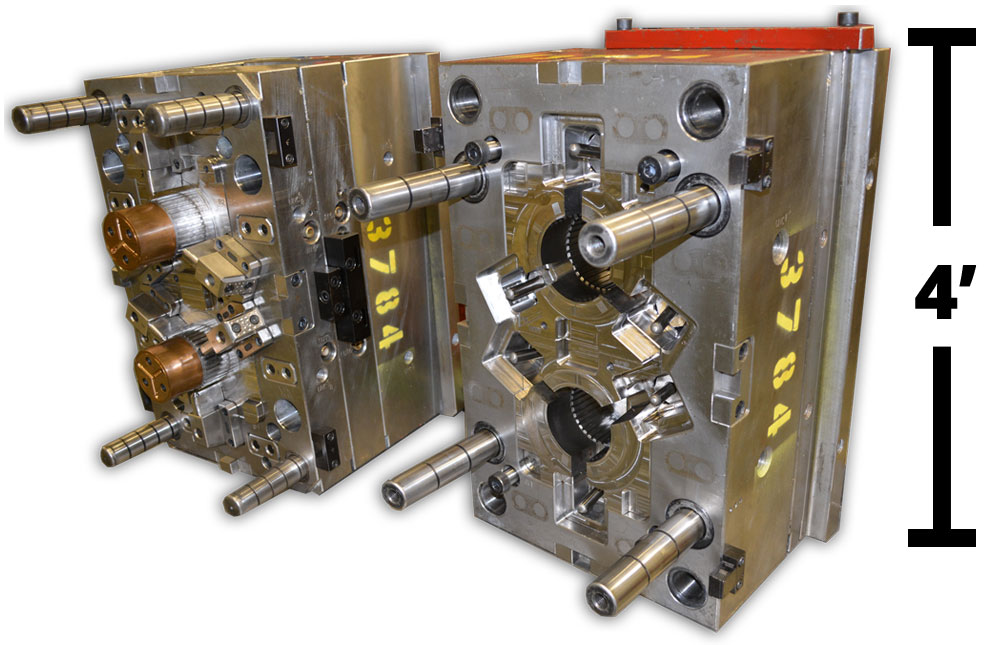

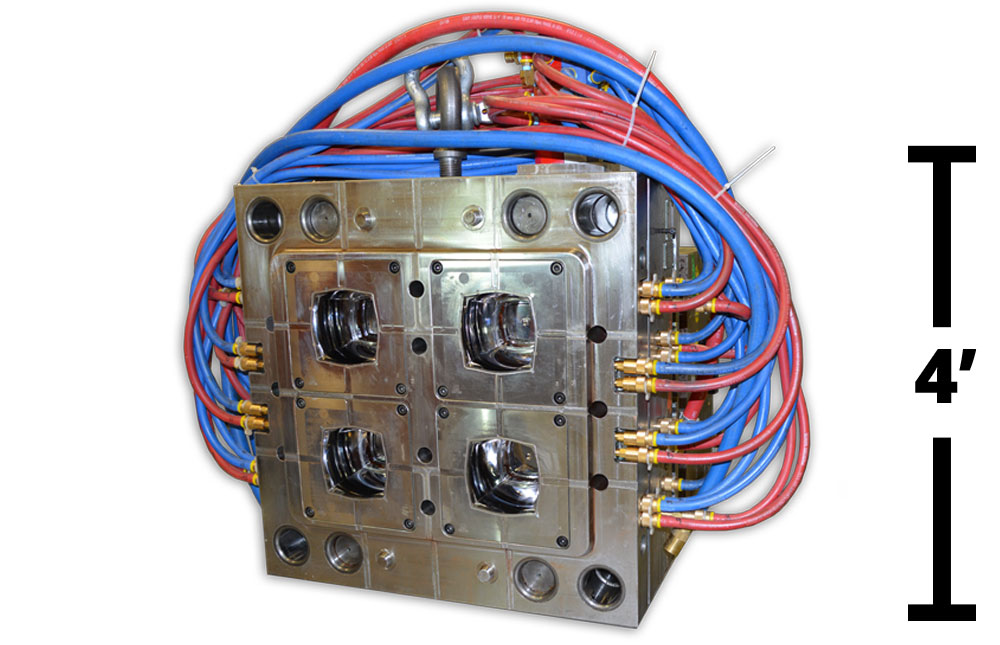

We offer a high quality, in-house tool shop for extremely fast turnaround. We utilize a global supplier network comprised of both domestic and overseas tooling solutions. Our tool shop employs a paperless system to support design, program, and construct your injection mold. Five Star Plastics is fully equipped with a tooling production and repair shop.

For customers that have already invested in tooling, Five Star Plastics offers tooling transfer programs that provide improved part quality, service, production time, and pricing. Contact Five Star Plastics with any questions you may have about transferring your existing mold.

Request a Quote

Tooling Services

- Plastics Industry Association Class 105-101 Molds

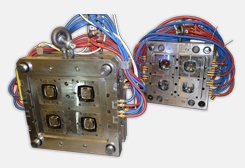

- Single Cavity to High Cavitation Tooling

- Two Shot Tooling

- Hot Manifold Tooling

- Insert Tooling

- Paperless System

Tooling Transfer Services

- Eliminate supply chain disruptions

- Tool transfer teams that go through a 94 Point inspection

- Document incoming tool inspection

- Document part quality

- Document tool quality

- Document any potential issues (tooling or part)

- Improving part quality, service, and pricing

- Tool cleaning

- Tool review

- Tool maintenance