Our Quality Policy is more than just a statement – it's a way of life.

Five Star Plastics quality teams operate within a robust Quality Management System (QMS). Our key to achieving tight tolerances and consistent aesthetics is maintaining control over the entire manufacturing process. We begin with a proficient process and then maintain it in mass production. Every shift has dedicated and trained quality technicians to ensure dimensional integrity is maintained and processes are controlled.

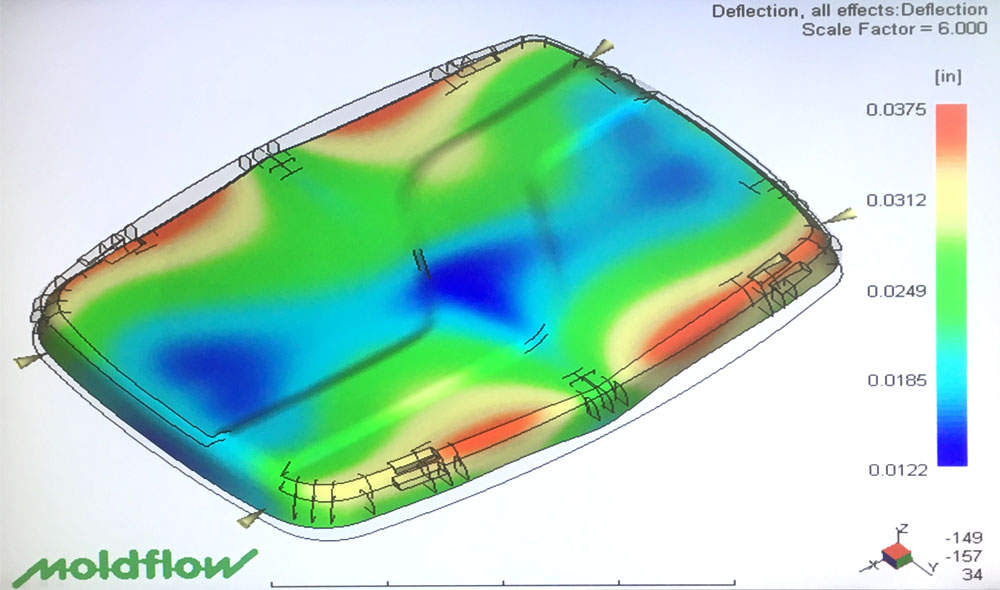

Our well-equipped on-site quality labs utilize CMM, optical gauging systems, and custom designed functional testing. We deploy the necessary activities and tools to ensure the appropriate levels of verification, validation, and monitoring controls are achieved.

- AS 9100D and ISO 9001:2015 Certified

- Component Recognition Program of Underwriters Laboratories, Inc.

- ITAR Registered

With our quality assurance, you can have confidence in our ability to handle projects of all sizes and complexity.

Request a Quote

Quality Capabilities

- IQ, OQ, and PQ Validation Protocols

- FMEA

- Advanced Product Quality Planning

- Process Capability Testing

- GR&R - MSA

- FAIR

- PPAP

- Moisture Content Analysis

- Melt Flow Range

- First Piece, In-Process, and Final Inspection

- Live SPC for All Parts

- Force Testing

- Quality Control Equipment

- Large Frame DCC CMM

- Vision Systems with Redundant Operating Software

- Optical Comparator